Stamping parts

PIC-(Stamping parts

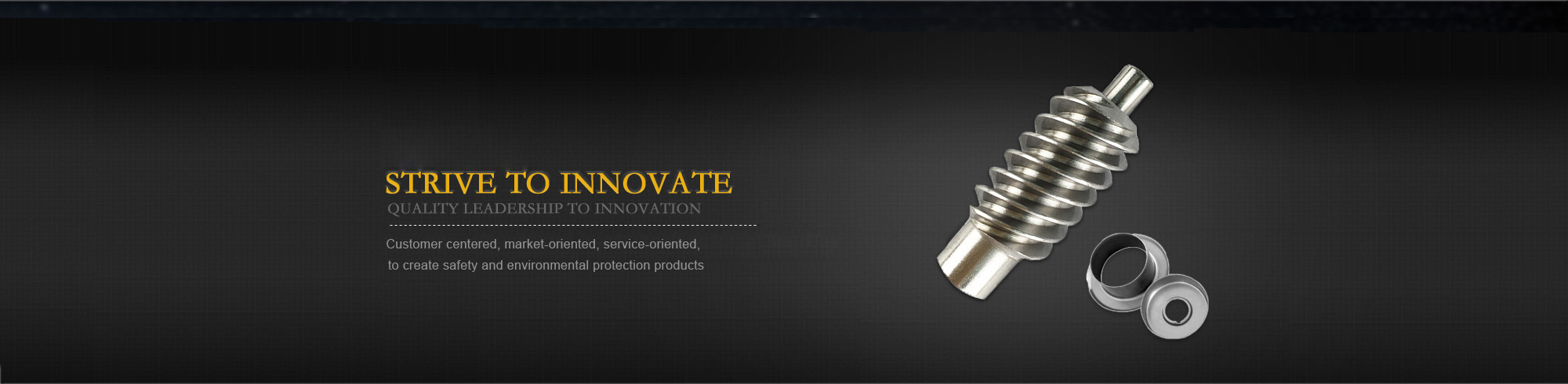

Stamping parts has high production efficiency and easy operation, and is easy to realize mechanization and automation. This is because stamping is completed by stamping die and stamping equipment. The stroke times of ordinary press can reach dozens of times per minute, and high-speed pressure can reach hundreds or even more than 1000 times per minute, and one stamping part can be obtained each time.

In the stamping process, the surface of the workpiece only contacts with the pressure liquid, and the pressurization process is gentle. Therefore, the stamping parts have uniform forming changes, which can obtain a uniform pressure distribution and obtain a much better smooth outer surface. The key is to shorten the processing time and realize mass production.

Of course, before the production of stamping parts, it is necessary to carry out a comprehensive and detailed inspection of the materials to ensure that they meet the production conditions, so as to avoid problems extending to the workpiece. According to the past experience, the selection of stamping parts materials should take into account the brand, thickness, size and so on. It is possible to produce high-quality stamping parts only by selecting reasonable plates.

When selecting the processing plant of stamping parts, attention should also be paid to the design of stamping parts. The drawings approved by the specified procedures must be in strict accordance with the relevant standards of the industry; the accuracy of stamping parts; and the requirements of stamping parts and mold technology. The mold should also be manufactured according to the approved drawings, so as to improve the product quality and increase the service life of the mold.

Considering the importance and particularity of stamping parts, it is necessary to ensure the integrity of functions during production or storage. Therefore, it is a good way to put them in sealed boxes or relatively closed spaces, so as to avoid the products from being fully protected.

Compared with other workpieces, stamping parts have the characteristics of light weight, thin thickness and good stiffness. Its dimensional tolerance is guaranteed by the mold, so the quality is stable and can be used without mechanical cutting. In addition to the traditional stamping parts made by press and steel die, various special stamping processes such as hydro forming, spinning forming, superplastic forming, explosive forming, electro-hydraulic forming and electromagnetic forming have also developed rapidly, and the stamping technology level has been raised to a new height.

Contact: Mr. Guo

Contact: Mr. Guo Mob: +86-183 3300 0079

Mob: +86-183 3300 0079 Tel: +86-317-5299861

Tel: +86-317-5299861 Add: Tiancheng Fortune Center, Yunhe District, Cangzhou, Hebei

Add: Tiancheng Fortune Center, Yunhe District, Cangzhou, Hebei